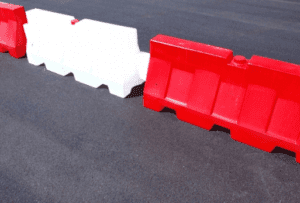

K-rails are protective concrete barriers, most commonly used to prevent access to prohibited areas and as a highway divider. These k-rail barriers can also be used extensively in construction sites, oil fields, nuclear power plant and more to enhance site safety. Introduction of mini k-rail barriers have made them portable and easy to rearrange. The usage of these K-rail barriers can also be multiplied manifold by their use as perimeter protection or as protection from heavy equipment in a construction site or power plant.

Only getting high quality k-rail barriers help you to meet the unique safety needs at the job site. Here are a few important qualities to look for in a K-rail barrier before buying them.

Safety

K-rail barriers are used in the job site to improve the safety of the workers working around a particular area. So, it’s important to ensure that the k-rail barrier is free from protruding bars and other materials that pose an impending danger. They should also be sturdy enough to be set in place and should not fall to cause serious injuries.

Quality of the Material

The longevity of the k-rail barriers is the important factor to consider while choosing the best k-rail option. Check whether the material used in the make of k-rails can withstand extreme temperatures and adverse outdoor conditions.

Portable and Flexible

The k-rail barriers you choose must be flexible, so that you can use it for both indoor and outdoor activities. Also, they should be portable, hence can be carried easily without much difficulty to different venues.

Maintenance and Cost

Look into the factors like the frequency of maintenance, the complexity of the maintenance process and the cost of doing it before choosing one. They should require less maintenance at a fair price and last for a long time.

Moreover, choose k-rails with the right balance of quality and economy to improve your site safety and enhance perimeter protection.